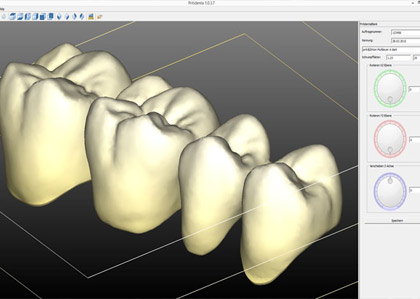

priti®multidisc ZrO2 multicolor Extra Translucent

For all open milling machines that accept round blanks with a diameter of 98.5 mm

priti®multidisc ZrO2 Extra Translucent is the most flexible zirconium dioxide, for all indications - a real all-rounder. It combines strength with aesthetics, the genuine, natural zirconium dioxide option for you.

(4Y-TZP) available in 7 color gradients and 1 bleach shade, 45% translucence, flexural strength > 1,150 MPa. Adjusting the position in the same disc allows all 16 Vita shades to be achieved with just 7 blanks!

You can use priti®multidisc ZrO2 multicolor Extra Translucent to fabricate inlays, onlays, veneers, partial crowns, monolithic, fully anatomical and partially or fully veneered crowns and bridges (up to 16 pontics) and custom anterior and posterior suprastructures on natural abutment teeth and implants. Its unique feature is its balance between high translucence and high flexural strength. This means the material can be recommended without reservation for flexible use across a particularly broad range of indications.

MATERIAL

- Zirconium dioxide Type II, Class 4 (DIN EN ISO 6872)

- Flexural strength > 1,150 MPa

- High translucence of 45%

- Very high aesthetics

- CTE 10 ·10-6 · K-1

- Thin wall thicknesses of 0.4 mm for single crowns in the anterior tooth area and 0.6 mm in the posterior tooth area

- Precise edges and margins due to highly compacted material

- Veneering possible with any ceramic mapped to the CTE of ZrO2

- Cross-batch color fidelity

- Homogeneous block shading

- Color can be reproduced at any time

- Biocompatible

CHEMICAL COMPOSITION

- Zirconium dioxide (ZrO2/HfO2): 92.1 - 90.7 %

- Yttrium oxide (Y2O3): 6.65 - 7.95 %

- Aluminum oxide (Al2O3): < 0.2 %

- Other oxides: < 0.7 %

CONSTRUCTION

| Systems must be constructed of the following specifications: | Crowns | Maryland-bridges | 3-unit bridges | |

|---|---|---|---|---|

| Minimum framework thickness | anterior | 0.4 mm | 0.4 mm | 0.6 mm |

| Minimum framework thickness | posterior | 0.6 mm | 0.6 mm | 0.6 mm |

| Connectors | anterior | 6 mm² | 6 mm² | |

| Connectors | posterior | 9 mm² | 9 mm² | |

| Framework design | Anatomically shaped (supporting veneer ceramics); fully anatomical |