The priti®crown is the only CAD/CAM crown blank, which - without individualization or characterization- replicates natural dentition after simply polishing.

Product Description

The priti®crown is a homogenous, glass-ceramic blank, which has a dentine-enamel layer resembling natural dentition within its existing tooth shape. These prefabricated crown blanks are not made into a customary square block, but instead into a natural tooth shape.

The fact that the color graduation is already integrated within the blank, means these prefabricated crowns can reproduce the shade effects in natural dentition through computer aided processing methods.

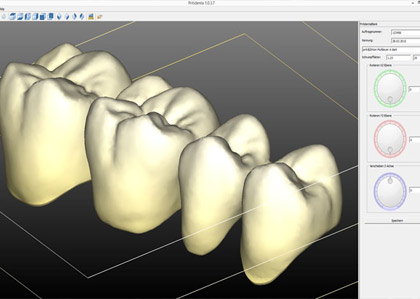

Image: priti®crown posterior tooth

Image: priti®crown posterior tooth

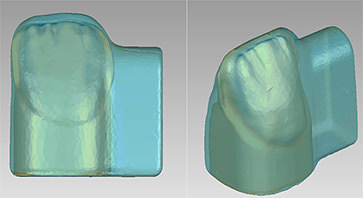

Image: priti®crown anterior tooth

Image: priti®crown anterior tooth

priti®crowns are industrially manufactured tooth blanks made from finely structured feldspar ceramic, which can be processed using various different CAD/CAM systems. They are characterized by their unique combination of feldspar materials and fine microstructure, which is different to other machinable silicate ceramics available on the market. This material has a high resistance to chipping, is abrasion-friendly when in contact with natural tooth substances and is easy to polish. The priti®crown is made from the well proven VITA Mark II ceramic.

Concept

The innovative priti®crowns were specially developed for highly aesthetical anterior restorations. pritidenta uses well proven terminology to classify the teeth to be replaced: “Spring, summer, fall and winter teeth”. The “spring tooth” describes a young, intact and almost untouched tooth. With increasing age and wear (“abrasion”), the shape and therefore also the color of the tooth changes. The main idea behind the priti®crown was to produce a young “spring tooth” (anterior and posterior) in layering and color, which is possible to customize according to the age of the tooth to be replaced, using the CAD/CAM process This technology enables the laboratory and dentist to use a fully computer aided process as an efficient production alternative to the traditional ceramic build-up technique. In addition to the excellent fluorescent, translucent and opalescent qualities, a special production process makes it possible to also use the chameleon effect.

Image: Comparison fluorescence: priticrown vs. Lithium Disilicate

priti®crowns have excellent machining properties. This is not only evident during the mechanical, tool-friendly grinding process, but also during post-production, intraoral grinding by the dentist. Shape adjustments and corrections can be easily and precisely carried out using a diamond grinding tool.

priti®crowns have excellent machining properties. This is not only evident during the mechanical, tool-friendly grinding process, but also during post-production, intraoral grinding by the dentist. Shape adjustments and corrections can be easily and precisely carried out using a diamond grinding tool.

Advantages

- High aesthetics:

- Economic efficiency:

- Great amount of working time saved:

- High degree of clinical safety:

The priti®crown is the only crown which can replicate the appearance of a natural tooth through simple polishing.

The different finishing variations enable a flexible price structure. The integrated color graduation makes an efficient and aesthetical restoration possible. This saves costs due to the fact that the crown simply needs to be polished. Characterization, individualization or thermal finishing processes such as stain and glaze firing or crystallization firing are unnecessary, but can be carried out at any time. With the priti®crown it is possible to achieve a highly aesthetical crown in considerably less working time.

In comparison to the classical build-up technique, this method involves far shorter working times due to the fact that the priti®crowns are made using an entirely computer aided production process.

Homogenous, finely structured feldspar ceramic VITA Mark II Highly reliable according to studies and experience reports over the last 20 years. More than 20 million inserted restorations

Breaking load values comparable to adhesively fixed lithium disilicate crowns Abrasion characteristics almost identical to that of natural enamel After clinical wearing time (7 years) the crowns have a survival rate of 97%

Advantages

- Abrasion characteristics similar to natural dentition:

The fine structure of the priti®crown produces abrasion characteristics similar to that of natural enamel and is therefore extremely gentle to antagonist teeth.

These enamel-like physical properties are created by the priti®crown’s fine crystal structure.

Portfolio

priti®crown sizes, shapes and shades

Anterior:

| Sizes: | S, M, L, X |

| Upper shapes: | Q (Square), R (Round), T (Trapezoid) |

| Lower shapes: | Sone shape |

| In 9 VITA shades: | 0M1, A1, A2, A3, A3.5, B2, B3, C2 and D3 |

| Posterior: | |

|---|---|

| Sizes: | S, M, L, X |

| Shapes: | one shape |

| In 9 VITA Farben: | 0M1, A1, A2, A3, A3,5, B2, B3, C2 and D3 |

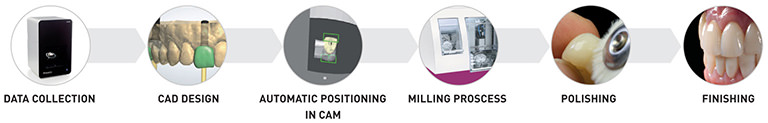

All sizes and shapes can be found in the tooth library, which automatically helps with the selection of the ideal crown during the design process.

System Compatibility

priti®crowns have a universal holder system for open CAD/CAM systems:

| imes-icore GmbH | 140i, 240i, 250i, 450i, 550i, CORiTEC Serie |

| vhf camfacture AG | K-/S-Modelle |

| DMG Sauer | ULTRASONIC 10 |

| MIKRON | HSM 400U |

| Dental Concept | DC5 |

| Röders | RXD4, RXD5 und RXD5C |

| MB Maschinen | Cobra Mill 5M, Cobra Mill 5A1, Cobra Mill 58 |

| Organical | Multi |

CAD Integration

The software required for the design of the priti®crown is available as a free-of-charge “add-on” and can be simply installed into your CAD software by exocad Dental CAD or the 3shape Dental Designer.

CAM Integration

priti®crowns are integrated within the following CAM systems:

Delcam

DS CAM 3

Hyperdent

ICAM V4.6

ICAM V5

ICAM 140i

OrganicalMill

Unique CAM

SUM3D

Work NC

| Oxide | Weight-% |

| SiO2 | 60-64% |

| Al2O3 | 20-23% |

| Na2O | 7-9% |

| K2O | 6-8% |

| CaO | 0,3-0,6% |

| TiO2 | 0-0,01% |

Material properties

| Flexural strength: | < 152 MPa |

| Breaking point: | <1,37 MPa · m½ |

| E-Module: | 57,2 GPa |

| CTE: | 10-6 · K-1 9,4 ± 0,1 |

Flexural strength

The priti®crown is exclusively for use as a single unit crown, in the anterior or posterior region. The degree of flexural strength is less important in single unit crowns. The flexural strength is measured in MPa. This involves the application of a spontaneous load with single, but ever-increasing tension, until the test object breaks. With anterior restorations this is not of great importance, the flexural strength only applies for 3 unit bridges upwards.

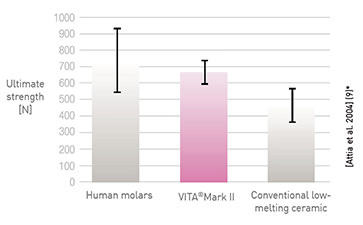

Comparison diagram of the 3 point flexural test with the failure of conventional bridges frameworks.

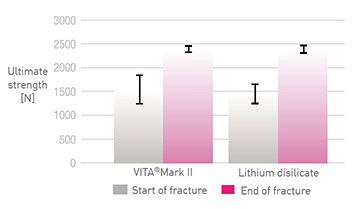

Breaking strength

The most important strength value for single crown restorations such as the priti®crown is the breaking strength. In this test, the entire restoration system including prepared tooth, adhesive fixation and real crown (shape, material) is placed under pressure as it would during natural masticatory force, until it fails (see pic.).

Festigkeitswerte

| Material | Fracture start | Fracture end |

| priti®crown | 1500 N | 2300 N |

| e.max CAD | 1500 N | 2300 N |

Strength properties

The reliability of a material is determined by the Weibull module. In this test, identical objects (bending bars) are loaded repeatedly until they break. These values are calculated to create the Weibull module. This describes the scattering behavior of the strength of ceramic materials. The higher the Weibull module, the lower the scattering, and therefore the higher the material reliability.

| priti®crown | 13.18 |

| Lava Ultimate | 9.02 |

| Empress | 5.93 |

| e.max CAD | 3.2 |

Quellen: ???